官方二維碼

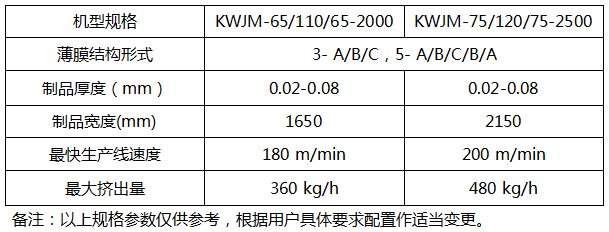

High efficiency single screw plastic single and multi-layer co extruded film production line R & D and production of the company's use special screw extruder, high precision casting mould, automatic control unit of the advanced cross double loop cold roll casting structure and casting of positive and negative pressure air knife system, cutting and waste material recycling system, film winding tension the control system and the international well-known brand PLC man-machine interface and control module of the automatic control system and so on. This series of equipment is made by tape casting process. It can produce optical grade PP film, optical grade rainbow film, CPP packaging film, high-grade PE substrate film, high-grade PP substrate film, fresh-keeping film, winding film and stretching film and other products. The unit has many advantages, such as reasonable structure, convenient operation, advanced technology, less energy consumption, high efficiency, uniform film products and smooth coiling. It is mainly aimed at the field of high-speed multi-layer co extrusion casting film with narrow width (2500mm), which is an ideal device for producing plastic film packaging materials.

High quality single layer / multi-layer coextrusion products are used in many fields:

1, polypropylene tape casting CPP: including stationery film, food composite packaging film, cooking film, embossing diaphragm, tablecloth film, barrier film, etc., and used for producing metal film and vacuum aluminized base film, etc., and has wide uses.

2, stretch wrap film: LLDPE series co extrusion tape casting stretch wrap membrane, used for manual or mechanical packaging of goods wrapped on pallets, home fridge preservation, and some farming and animal feed production. The 10 micron thick self adhesive mold, produced by the mixture of LDPE and LLDPE, has excellent tensile and retraction wrapping.

3, preservative film: fresh film of fruits and vegetables.

4, the diaphragm base material for lithium battery.