官方二維碼

Plastic hollow board is the best substitute for plastic instead of wood and plastic instead of paper. It is the key product to meet the requirements of environmental protection in the new era. It has been widely used in home appliances, electronics, automobiles, machinery, logistics, glass, advertising, food, medicine and other industries. The main products are: conductive antistatic hollow board, antistatic hollow board, flame retardant hollow board, wantong board, the advertising board and glass plate, vegetable and fruit packing box, hollow board turnover boxes and car, pesticide packaging box, refrigerator backboard, refrigerator bottom bracket, billboard, display box and various plate inserted board, partition board, liner.

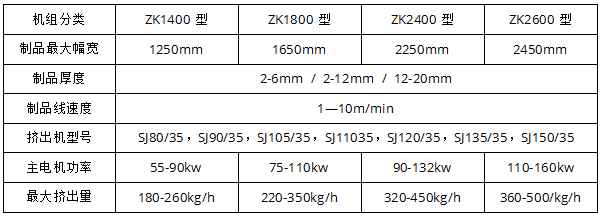

Basic technical parameters of plastic hollow plaid production line:

High performance hollow grid plate production line series of Lizhi Company and special mould, has advanced technology, wide applicability, stable performance. According to the differences of product width, thickness, structure, hollow shape and use of plastic raw materials, we have different classifications:

1. According to the width of the product, it can be divided into ZK1400, ZK1800, ZK2400 and ZK2600

2. According to the thickness of products, we can support 2-6mm, 6-12mm, 12-18mm special hollow lattice plate die

3. According to the product structure, it can be divided into single layer plate, double layer coextrusion plate and multi layer coextrusion plate

4. According to the shape of products, it can be divided into basic type --I type, special type --S, V type, X type, rice type, etc.

5, According to the use of plastic materials for products: the high speed and high efficiency plastic extruder can be applied to PP, PE, PC and other raw materials.

Hollow grid unit configuration list:

1. High speed and high efficiency single screw extruder

2. Dry hopper + automatic feeding machine

3, Non stop hydraulic rapid net exchanger

4. Hollow lattice plate mold

5. Vacuum setting device

6, The first traction mechanism

7. Hot drying setting device

8. Cold wind setting device

9, Second traction mechanism

10. The cutting mechanism of sheet material

11. Heap platform

12. Electronic control system

13, Optional: automatic screw feeding machine + forced feeding machine crushing hopper, cold water machine and cooling tower, scrap recycling machine.